high torque magnetic coupling motor price

Brand: magnet forever

Product origin: china

Delivery time: 40-60 days

Supply capacity: 5000 units

Non-contact coupling.

No gear linkage, no need to use lubricating oil.

Synchronous coupling and hysteresis coupling.

High torque magnetic coupling motor price

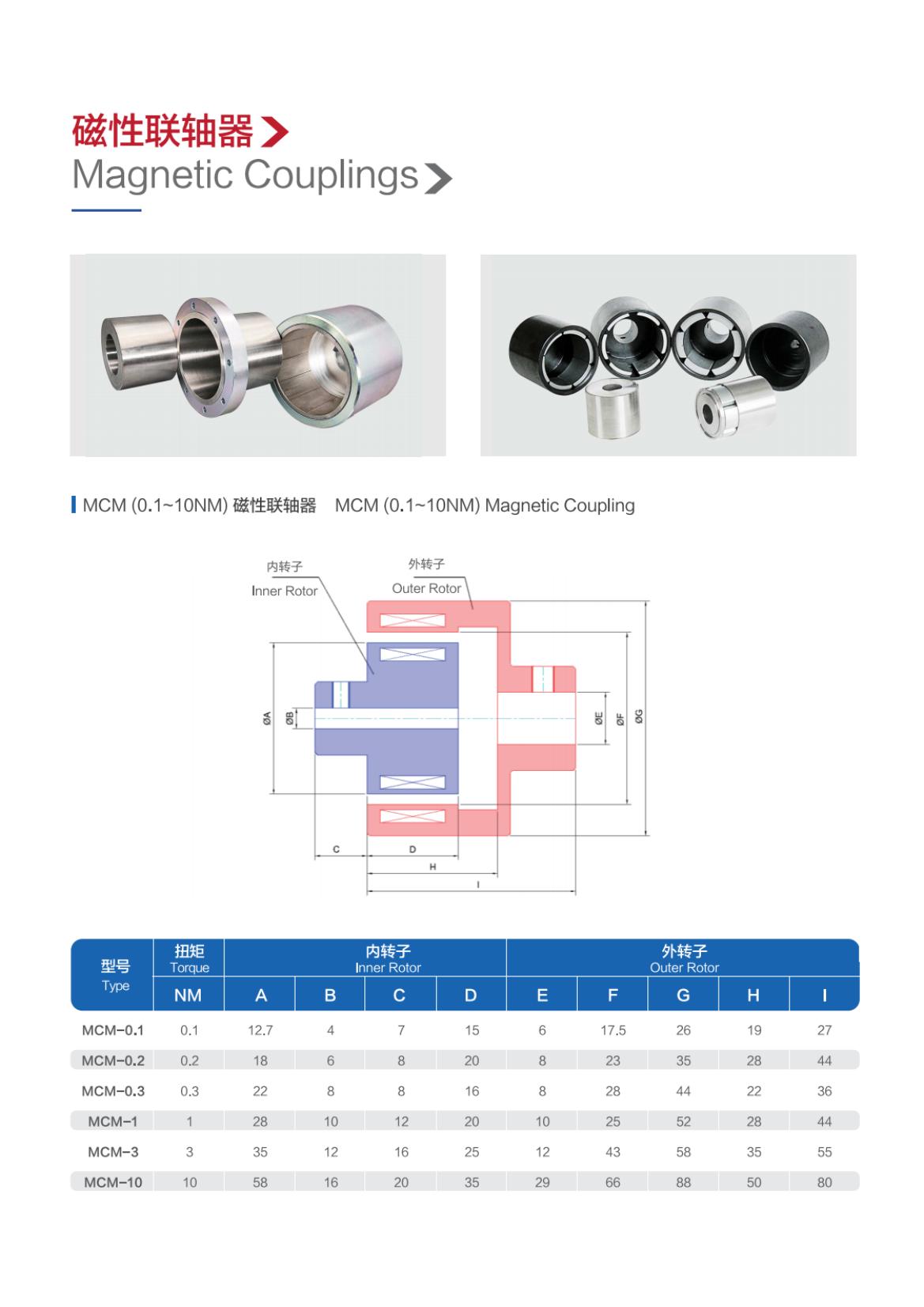

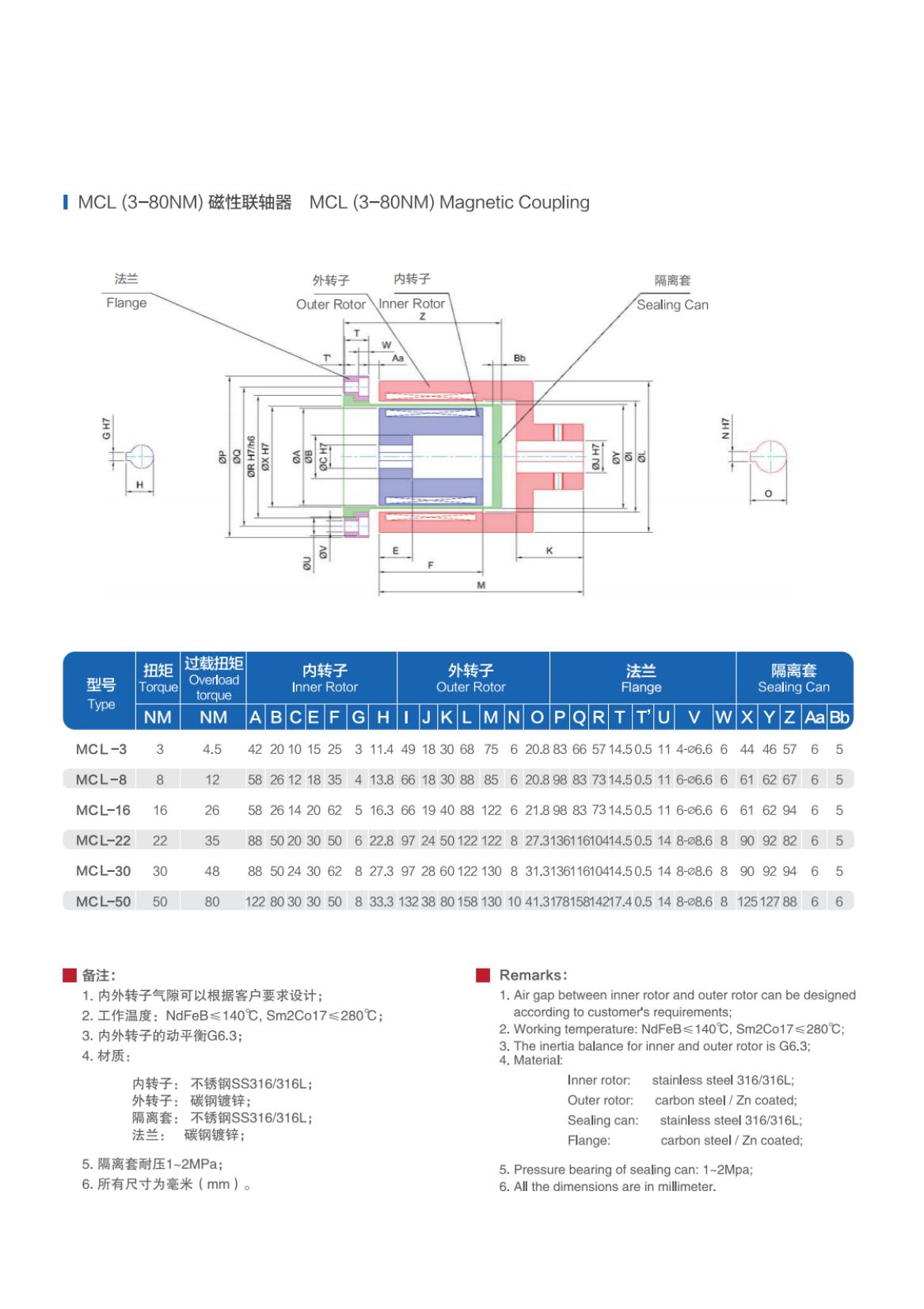

The magnetic drive coupling is a non-contact coupling. It is generally composed of two magnets inside and outside. The two magnets are separated by an isolation cover in the middle. The inner magnet is connected with the driven part, and the outer magnet is connected with the power part. In addition to the elastic coupling's function of buffering and absorbing vibration, the magnetic drive coupling has the biggest feature that it breaks the structure of the traditional coupling and adopts a new principle of magnetic coupling to realize the non-passing between the driving shaft and the driven shaft. Direct contact can transmit force and moment, and can transform the dynamic seal into a static seal to achieve zero leakage. Therefore, it is widely used in occasions with special requirements for leakage.

Application of magnets in magnetic couplings:

The invention and development of magnetic drive couplings are closely related to the continuous emergence of new permanent magnetic materials. The first used ferrite material, which has a wide range of material sources and low price, but due to its poor magnetic properties, it can only transmit a small torque in the same volume as the traditional coupling, thus limiting the magnetic force The development of couplings. The second-generation permanent magnetic materials are samarium cobalt (SmCo5, Sm2Col7) and aluminum nickel cobalt (AlNiCo). Its magnetic properties are greatly increased compared to ferrite materials, so that the magnetic coupling can transmit larger torque. However, the reserves of samarium, cobalt, and nickel used in samarium cobalt and alnico are scarce and are scarce and expensive strategic materials, so the price is high, which restricts the development of magnetic drive couplings. The rare earth neodymium iron boron (NdFeB) permanent magnet material has a maximum magnetic energy product (BH) max of 286 6kJ/m, becoming the third-generation permanent magnet material after samarium cobalt and alnico. Neodymium-iron-boron (NdFeB) is not only more excellent in magnetic properties, but also rich in raw material resources. It can replace cobalt with cheap iron (Fe) and replace samarium with abundant neodymium (Nd), so its price is lower than samarium cobalt and aluminum nickel cobalt. , Market competitiveness is strong, easy to promote and apply. At the same time, the magnetic energy product of NdFeB is high, the amount required is small, the processing performance is good, it can be cut and drilled, and the yield is high, so it can reduce the volume of the magnetic drive coupling, reduce costs, improve efficiency, and save energy. It is widely used in magnetic drive couplings.

With the development of magnetic materials and the emergence of new magnetic materials, the torque transmitted by the magnetic drive coupling will become larger and larger, and the volume will become smaller and smaller, and its application range will become wider and wider, except for pumps and reactors. , Valves, hydraulic cylinders and cylinders, and other occasions that need to solve the problem of dynamic seal leakage can be applied. It can be predicted that the magnetic drive coupling will have a very broad market prospect.

Magnetic drive couplings have formed a professional standard in industrialized developed countries, and finalized products are sold in the international market.