Company news

Application of Neodymium Magnets

Magnet and Magnetism

global vision of Magnets

Industry news

Product news

Agency Invitation

Magnetic Couplings

04-06

/ 2025

The calculation results of the calculation models found online vary greatly, which one is more accurate? Is there a corresponding relationship between surface magnetism and residual magnetism?

04-04

/ 2025

Sintered neodymium iron boron permanent magnets are the highest magnetic materials discovered so far, widely used in various fields such as wind power generation, new energy vehicles, maglev trains, intelligent robots, etc. Sintered neodymium iron boron magnets use powder metallurgy technology, and the raw materials contain highly active rare earth elements, which deteriorate their corrosion resistance in high-temperature and high humidity environments, greatly limiting their use in various complex working conditions. This places higher demands on the comprehensive performance of neodymium iron boron magnets in practical applications.

04-02

/ 2025

Sintered neodymium iron boron permanent magnet materials have excellent performance and are widely used in fields such as automobiles, home appliances, wind power, and consumer electronics. They are currently the most important type of permanent magnet material in the market. In recent years, with the booming development of the electronic information industry, wind power, and new energy vehicles, the demand for neodymium iron boron has been increasing, and the annual output of sintered neodymium iron boron has gradually increased. During the production process of sintering neodymium iron boron, a large amount of production waste is generated. At the same time, more and more electromechanical equipment containing neodymium iron boron magnets are being scrapped, resulting in a large amount of neodymium iron boron waste. The rare earth element content in neodymium iron boron materials accounts for more than 30%, and rare earth resources are non renewable. Using economically effective methods to recycle valuable substances from neodymium iron boron waste can create certain economic value, save resources, and reduce environmental pollution.

03-31

/ 2025

Parylene is a new type of conformal coating material developed and applied by Union Carbide Co. in the mid-1960s in the United States. It is a polymer of para xylene, which can be classified into various types based on its molecular structure, such as N, C, D, F, HT, etc.

03-23

/ 2025

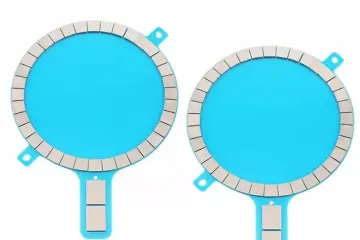

Halbach Array (Halbach permanent magnet) is a type of magnetic structure. In 1979, American scholar Klaus Halbach discovered this special permanent magnet structure during electron acceleration experiments and gradually improved it, eventually forming the so-called "Halbach" magnet. It is an approximate ideal structure in engineering, which uses the arrangement of special magnet units to enhance the field strength in the unit direction, with the goal of generating the strongest magnetic field with the minimum amount of magnets.